WE are one of the leading engineering company in Mumbai (India) connected with Paint Shops/Engine Shop/ Assembly shops etc., for automobile industries. AtTrishul we believe in interweaving of the capabilities of various departments of our clients to enable him to achieve:

Deliberations with our clients at various stages of the projects and moulding of our R&D to cater to his need are the salient features of our project management technique.

Trishul believes that the total quality guarantee can be ensured by following the full circle viz.:

The zero defect quality solution is very necessary for warships, nuclear installations etc. and Trishul had the opportunity to deliver its services in such sectors. In Pharmaceutical and Chemical industry also Trishul's inherent principle of zero defects plays a significant role.

With many years of experience in automobile paint shop Trishul has pin pointed the areas of concern for quality such as:

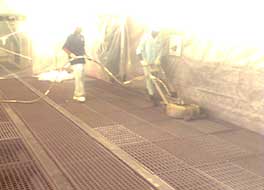

Trishul has developed methods of truss / wall cleaning which includes

The above method has proved very effective compared to the conventional methods. Trishul has always taken the lead to induct Hi-Tech

methods of cleaning e.g.:

We have vast experience of extensive cleaning in the following areas:

While executing a cleaning process in any type of industry we strive to create a data bank for our client which offers the first hand information to them our about:

This data bank works as a pathological report of the plant providing our client ample time to take the counter measures. This methodology bears a direct weightage on the quality improvement and results into following benefits: